Sticky Solenoids and Possible Solutions

Sticky Solenoids and Possible Solutions

HP, Canon, Brother, Dell, and many others... they all have a problem with sticking solenoids. When they put the machines together, they put little pads on the solenoids to keep them quiet. Those pads disintegrates over time, and then instead of a pad, it becomes a sticker--and it makes the plates on the solenoid stick, instead acting as a cushion.

Technicians have different ways of dealing with this. Some of them just replace the solenoids. The problem with that is there are so many different kinds, and you'd have to keep a wide variety of them for a lot of different machines... or leave the customer down while you order one.

Some guys just clean off the disintegrated padding. The problem with that is the metal plate that comes into contact with the electro-magnet becomes magnetized (because it's too close to the magnet) and it sticks--the same as it did before cleaning off the padding.

A lot of guys just repad them. Nothing wrong with this--but it takes a little while and you have to hope the glue doesn't wear off or and the padding doesn't fall out and cause some other problem.

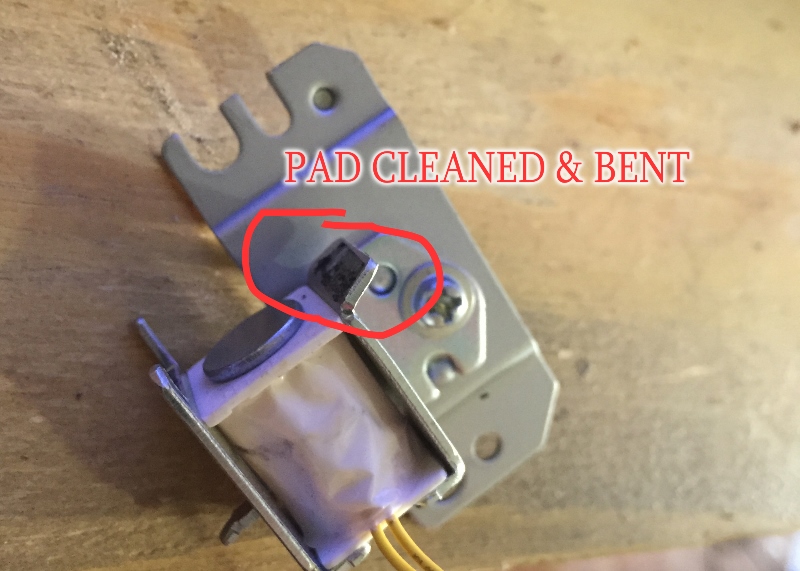

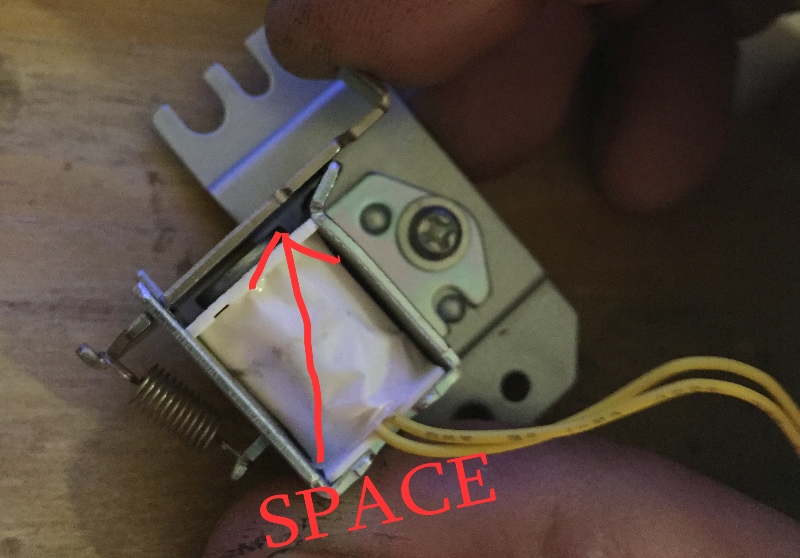

Here's by solution. Bend the metal plate on the solenoid as shown in the pictures below. You don't need extra material, and the plate never magnetizes and comes back to haunt you.

I've been doing it this way for years, and have never been called back on one.